Pets Tracker

TSC Plasma provides mold design and mass production of materials for pet trackers. And combined with the LDS process, the three-dimensional antenna is produced, and the product has more space to shrink so that the battery or circuit board (PCB) of the product can be used more.

Because the pet tracker needs to be waterproof and impact-resistant, after the assembly is completed, the impact-resistant material warrping injection molding with the TPU material is also used.

DRAM Heat Sink

TSC Plasma provides machining and surface treatment of metal heat sinks. Under the continuous growth trend of PC's pursuit of heat dissipation, there are many products that need heat dissipation and appearance.

TSC Plasma has a long and rich experience in metal processing and surface treatment, and can definitely meet the needs of customers and take into account the quality.

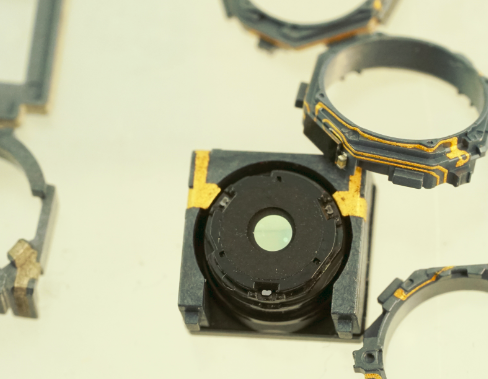

Camera lens with LDS process

With the trend of thinner and thinner mobile phones, many manufacturers have begun to develop and make the lens smaller. LDS circuit is the best solution.

The chips and resistors and capacitors originally placed on the pcb board were successfully assembled into the Lens lens module through the characteristics of the LDS circuit. Considering the vibration of the mobile phone, we additionally add non-conductive adhesive and underfill it on the bottom of the chip to make it shock-resistant and not easy to fall off.

PC personal computer button

In recent years, PC personal computers have increasingly pursued texture, and TSC Plasma is the leader in providing such metal surface finishes. TSC Plasma has been OEM for Apple's supply chain for more than ten years, and has passed the supply chain audit every year.

TSC Plasma has a lot of experience in manufacturing metal processing and post-fabrication surface treatment.

SSD

SSD and HDD have their own indispensable characteristics, TSC Plasma can provide the casing and decoration of SSD.

Allows brand manufacturers to focus more on the internal configuration of the SSD to improve performance.

MIM Products

Materials used: various materials such as stainless steel, iron-nickel alloys, etc.

Mass production, high output efficiency Forming of complex parts Combined design of components to reduce cost of parts and increase assembly accuracy Application industries: electronics, industry, medical, shipping, military

Earpods Shell Production and Despensing LOGO

In consumer electronic products, among which earphone products, TSC Plasma provides plastic injection molding and mass production of materials, and has a production line from start to finish for subsequent surface treatment. Like NCVM (Plating) and LOGO Despensing.